COMPETENCIES

Materials and Water Chemistry Control for Safety/Reliability of Nuclear Power Plants

FNC has a full range of experiences designing both commercial power reactors as well as experimental and research reactors.

BEYOND THE FUTURE

WE FLY, WE NEVER FALL

Secondary coolant system

Single phase phenomena

Two phase phenomena

Various metallic alloys are being used most extensively as structural materials for water-cooled reactors.

Considerable activities have been conducted to ensure that metallic components can protect the nuclear power plant and thus, provide the reliable safety during the operation of participated life and beyond.

In addition, since severe accidents by the earthquake and tsunami at the Fukushima Daiichi nuclear power plant in 2011, the primary attentions have been given to development of nuclear materials that enhance the accident tolerance of water-cooled reactors to tolerate loss of active cooling in the core.

Degradation and failure of metallic components have been occurred at various locations and posed a major concern because of difficult replacement of certain large components.

Thus, the importance of water chemistry control becomes increasingly obvious, especially at the geometry in the bulk environment that could give rise to unfavorable localized conditions, and numerous efforts have been focused for optimizing the water chemistry condition at nuclear power plant.

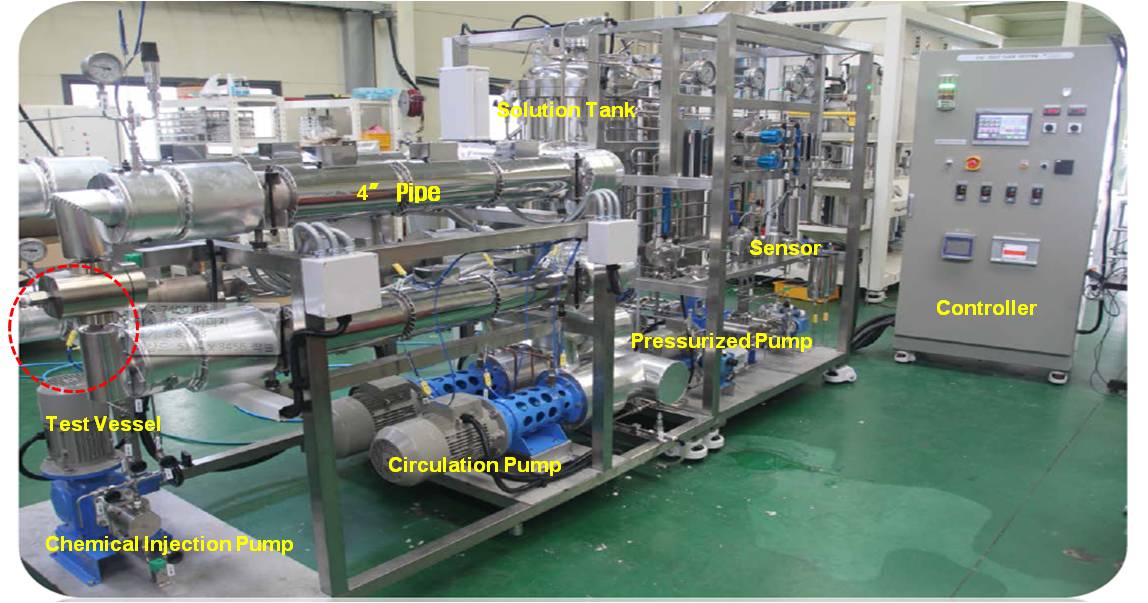

FNC Technology organizes a technical team to establish the capability of experimental system for simulating light water reactor water chemistry conditions and various government funded projects are under progress to identify the root-causes of degradation of nuclear components and eventually develops the prediction model and life extension methodology.